Building On Contaminated Land and Protective Ground Gas Barrier Membranes: Regulations and Best Practice

Building On Contaminated Land and Protective Ground Gas Barrier Membranes: Regulations and Best Practice

As the UK grapples with a severe housing shortage, the pressure to build new homes has never been greater. While greenfield development often faces opposition due to environmental concerns and community impact, brownfield sites—former industrial, commercial, landfill or contaminated land—present a significant, yet underutilised, solution. However, with this opportunity comes the challenge of ensuring safe living conditions in places that may carry remnants of past contamination.

Effective ground gas barrier membranes are essential in protecting new developments on these sites, acting as a shield against harmful substances. They are also essential for developments in areas where radon and methane have naturally formed. To minimise the risk of ground gas and vapours from historical spill areas it’s vital to observe the correct guidance and identify the most suitable under-floor protection measures to prevent the migration of contaminants into buildings.

Common types of land contamination

Land contamination can involve a range of substances, each requiring specific protective measures. Major contaminants in the UK include methane, carbon dioxide, radon and Volatile Organic Compounds. Methane is flammable gas that poses an explosion risk. Carbon dioxide becomes hazardous at high concentrations, often present on brownfield sites. Radon is a radioactive gas found in granite-rich areas, linked to lung cancer with long-term exposure. Volatile Organic Compounds (VOCs) are harmful chemicals from industrial activities that can vaporise and infiltrate indoor air. They include benzene, toluene, and other hydrocarbons.

Key regulations and standards for protection against contaminants

The primary UK standards governing building on contaminated land and ground gas barrier membranes include BS8485, a standard that addresses protection against methane and carbon dioxide, offering a points-based system to achieve appropriate protection levels. For instance, if a membrane scores two points under BS8485’s criteria, it meets Table 7 requirements, designed to prevent gas ingress.

The NHBC uses a Traffic Light System to provide a risk-assessment approach for site contamination using a color-coded system, ranging from green (low risk) to red (high risk), indicating the level of contamination.

Construction Industry Research and Information Association (CIRIA) is a neutral, independent and not-for-profit body that provides guidance on the installation and verification of ground gas protection systems and the use of membranes as barriers against volatile organic compounds (VOCs). CIRIA have released two documents – C735 and C748 – on the installation and verification of ground gas protection measures and the use of membranes as VOC barriers.

BR414 is an important document with reference to protective measures for housing on gas-contaminated land. Its standards specify the minimum requirements for using ground gas barrier membranes to prevent radon ingress, particularly in radon-prone areas.

Gas transmission rate is a key metric in the performance of a gas barrier membrane. This should be tested in accordance with EN15105-1.

Types of ground gas barrier membranes

Ground gas barrier membranes come in various forms designed to block specific contaminants and gases from entering buildings.

These include gas barrier membranes designed to prevent the ingress of methane and carbon dioxide, providing a critical function in protecting building occupants from toxic exposure. BS8485 is the main legislation currently followed for membranes used for higher levels of methane and carbon dioxide. The standard came into use in 2007 and has had three amendments, the latest edit is BS8485:2015+A1:2019.

BS8485 table 7 requires the methane and carbon dioxide membrane to be “not significantly less than 0.4mm thick between the reinforcement scrim.” This statement has created uncertainty in the trade because it poses the obvious question of what is considered not to be significantly less. In Annex C of the standard, it also asks for “minimum 0.4mm for welding the membrane. The standard also allows for the membrane to be tape jointed. The membrane must also have a minimum gas transmission rate of <40ml/day/m2 atm in line with EN15105-1.

Some membranes are specifically designed to block radon from entering structures. To deal with radon, BR414 refers to the use of a minimum 300-micron radon barrier membrane of virgin polymer. However, the thickness of the membrane should be increased to 400 microns if it needs to be BBA-certified.

Some multi-layered membranes provide protection against multiple gases, including methane, carbon dioxide and radon.

Chemical-resistant membranes, or hydrocarbon-resistant membranes, are used for sites contaminated with hydrocarbons like petrol or diesel. These membranes prevent fuel vapours from migrating indoors. High-density polyethylene (HDPE) is commonly used, but HDPE membranes allow permeation, making them unsuitable for certain applications.

VOC barrier membranes are designed to prevent the entry of volatile organic compounds into buildings, protecting indoor air quality. Membranes which provide protection against multiple gases generally have aluminium cores. In our research into resistance to hydrocarbon and chemical spills, it was quickly ascertained that the aluminium core will delaminate and render the membrane useless. Written into the CIRIA C748, this is the main reason aluminium core membranes cannot be used for hydrocarbon sites. An effective VOC barrier should be a multi-layered membrane with a hydrocarbon-resistant core.

Some membranes are designed for dual-purpose, serving both as a waterproof barrier and a chemical barrier, protecting buildings from both water and contaminant ingress.

Assessing land contamination

Assessing land contamination is a complex process prone to inaccurate diagnosis, so attention to detail is essential. ITP have often been asked to advise the correct membrane specification on projects where the wrong membrane was originally chosen, usually due to a failure to read the contaminated land report in full.

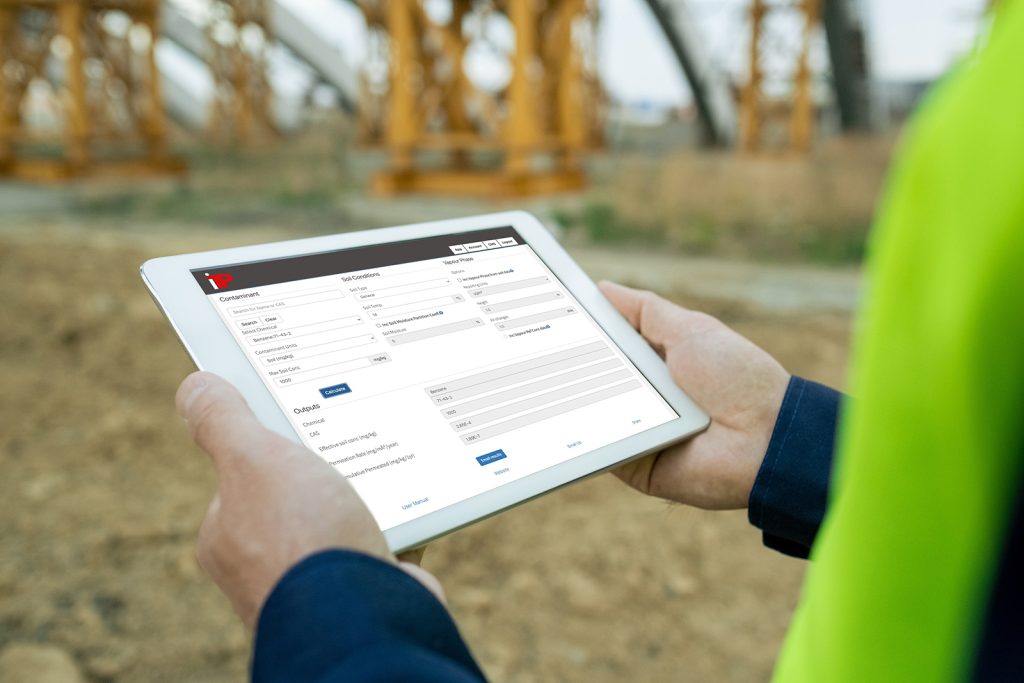

Accurate assessment requires software programs that model on the scientific parameters, identifying the permeation rate of a wide range of harmful chemicals and almost any given hydrocarbon. ITP’s unique software takes the amount of gas or vapour reading from the contaminated land report and produces a precise reading on the permeation rate of the challenge chemical when using certain membranes within the footprint of the build. Using our software takes guesswork out of the equation and streamlines the risk assessment process.

When the software demonstrates that the membrane reduces the vapour to below WHO recommended levels, the correct membrane solution is then determined and specified at the outset.

Installation considerations

Although membranes should be robust enough to withstand the installation process and the follow-on trades, care should be taken during the construction phase as most membranes should not be exposed to significant walk-over or foot traffic from site trades.

Membranes should be installed according to manufacturer specifications and British Standards. Most membranes are installed using one of two methods: welded with use of hot air welding equipment or taped and sealed joints.

Welding of joints in most of the membranes is always preferable, especially the higher end VOC type applications. It is not required by law but gives a better seal if professional installation is utilised. The membrane is essentially melted and fused together with a jet of hot air from a roller-type floor welder or a handheld welding gun. When using tapes, greater care is required in making sure all tapes are fitted and pressure compressed with a handheld seam roller. There are two main tapes for the overlap, butyl double-sided for the internal lap and single-sided foil tape for the overlap. We also recommend using ‘top hats’ and pre-formed corners where required.

Reclaiming and redeveloping contaminated land has the potential to play a huge part in addressing the UK’s housing crisis, but it requires detailed site investigation and strict compliance with standards to ensure safety. Accurate risk assessment and the correct choice of ground gas barrier membrane can unlock that potential, regenerating neglected and under-utilised land throughout the UK.

Need more advice?

Contact ITP’s Building Team on 01347 825200 or info@itpltd.com